Alright then.

This build is orders of magnitude more difficult than the curling bench. the preacher curl bench is a small, fully welded unit. One size fits all. No moving parts or adjustibility at all. The weight lifting bench is significantly larger, and widely adjustible in many areas and different axis, so of course it requires a significantly longer-winded introduction than the preacher bench did, and a several page thread.

To sum up my desires here, I need a multi-function Olympic weight bench that will fit the space I have available, but I am endlessly annoyed at the cheesy/cheap construction, limited functionality, strength, and materials used in any affordable “consumer-grade” equipment.

The units I’ve owned over the years all share similar shortcomings. They are constructed from 16 gauge steel tube which just barely makes the cut on strength, bare minimum welds, load limits are ridiculously light, and the adjustable parts are rickety and very limited in positions. Furthermore, the designers have made some choices based on “average” size/shape people that render some parts of the equipment unusable. Ridiculous since at 5′ 10″ I’m not super tall. The leg apparatus are clearly designed for pygmies 🙂 On top of that, the bench height is usually too high in order to allow room for the leg extension piece to function, so when performing flat bench press you cant brace your feet firmly on the floor. Ideal bench height is generally accepted to be 17-18″. the bench height of my most recent consumer-grade bench (before building this) is 22″ off the floor, and this is a fairly highly-rated bench (compared with other cheap, consumer gear). There’s no comfortable place for your legs, and while flat bench is a chest exercise, being able to firmly plant your feet provides half the stability you need for good pressing.

Lastly the leg apparatus is totally in the way when laying on the flat bench, which makes no sense because the bench press is arguably the main function of a weight bench like these. You would think it would be optimized for that function, but I guess looking for logic in a device designed by a committee of bean-counters is a pointless exercise 😉

Out of all of those, the strength (or lack thereof) of the equipment my primary concern. I’m not the strongest guy on earth, but I I’ve been strength training for a lot of years and I’m above average in strength. I use enough weight that it could definitely break the cheapo bench I was using, and if the bench broke at the wrong moment the results could be pretty bad. Every time I’m lifting heavy a part of my mind is imagining the bench collapsing under me. This makes for a nervous workout, and also detracts from what I can do in my training since I am not focused 100% on my task.

Reality is that in the world of exercise equipment, most people that are serious about strength training either work out at gyms, or they are able to equip home gyms with lots of single function free weight benches. ie: one for flat, one for incline, one for decline, etc.

There are several factors that manufacturers of consumer-grade equipment have to consider when designing their products.

- It must be cheap and fast to manufacture

- It must be easily disassembled and reassembled

- It has to be able to be packed into smaller boxes for easy shipping

- It has to be fairly light to avoid excessive freight costs

- It has to be “one size fits all”

- It has to maximize profit

Simply put, this is not a formula for producing high quality, durable equipment. Fortunately I dont have to consider any of those factors when designing one piece of equipment solely for my own personal use 🙂

The features I require are:

- The space-savings of multi-function equipment.

- The extreme high strength and durability of single function pro-grade equipment.

- Fully adjustable safety rails

- Leg apparatus hinged appropriately for my legs

- Completely removable leg apparatus

- Much smaller adjustment increments for more varied exercises.

- Proper bench height

- Affordable

Reality check: Equipment that meets all those criteria (particularly after adding the “affordable” requirement) doesn’t actually exist, so If I want it I’ll have to build it myself.

Also, the term “affordable” isn’t a fixed value. This number could be very different from one person to the next. In my case, given what I save building my own, my cost on materials was about the same as you would pay for a commercial-grade, heavy duty, single function, flat bench. An example would be one I had found on line for $899.99. Thats about what this home-brewed bench cost me. My design is its equal in strength, but far more versatile. That $900 model was only for flat bench press. Nothing else. If I broke my design down into its separate functions, this bench does the job of 7 separate pieces of single-function equipment:

- Flat bench press

- Decline bench press

- Incline bench press (unlimited angles)

- Upright shoulder (strict) press

- Squat/power rack

- Leg extension

- Leg curl

The removable cable/pulley apparatus adds many additional functions

- Cable flyes for incline, decline, or flat plane

- Cable curls

- Cable triceps extensions

- Lat pulldowns

There are actually multiple additional possible uses when combined with the cable apparatus, but I’ve listed enough to show the value of this machine

If you bought ten separate pieces of heavy duty, pro-grade equipment you’d likely pay well over $20,000.00, so when talking about affordability you have to think about that $900 I paid for materials as relative to that much larger price tag.

In reality the materials actually only cost me about $600, but thick-walled steel is not cheap to ship. About 30% of the overall cost was freight charges. In the end though I actually didn’t spend anything out of pocket at all since I funded the materials purchases entirely with the proceeds from selling a couple tools from my shop that I dont use. In the end it cost me nothing but the time I spent building it, and since I actually enjoyed the hell out of designing and building this equipment, the time wasn’t really a cost either 🙂

All the structural tubing is 11 gauge, not the industry norm of 16 gauge. For those not in the know, in the world of metal gauges the smaller the number the thicker the metal. So 11 gauge is literally double the thickness of 16 gauge, and the physics of the way steel works, when you double the thickness you multiply the strength by a factor of 8 so the resulting structure is 2x heavier and 8x stronger. Even more, actually, because I dont need to be able to break this down into small boxes that are easy to ship. I can still dismantle it to an extent, but most of the joints are fully welded as opposed to held by nuts and bolts, and the joints that are using nuts and bolts have 1/4″ thick welded flanges and 1/2″ bolts, and so are also significantly stronger than their consumer-grade counterparts that usually use 1/4″ or 3/8″ bolts. Weight rests (and safety rails) are fully welded and held at any given position by two hardened and tempered (by me) pins made from W1 tool steel. The weakest link in this bench, the cross beam that the bench back rests against, will support upwards of 3500 lbs. That should be enough 😉

The leg apparatus are designed with measurements that work with my own legs, and its completely removable so its not in the way while doing other exercises.

Now, I didn’t re-invent the wheel here. This type of equipment has been around a long time and is fairly simple in design. I took inspiration from several different benches I’ve owned over the years, as well as equipment I’ve used in other gyms, and incorporated all the features I liked the most into this one piece of equipment. I deliberately chose materials and construction methods that will provide the maximum in strength and durability, and then customized all the specs (bench height, length of legs, etc) so that they will work for me.

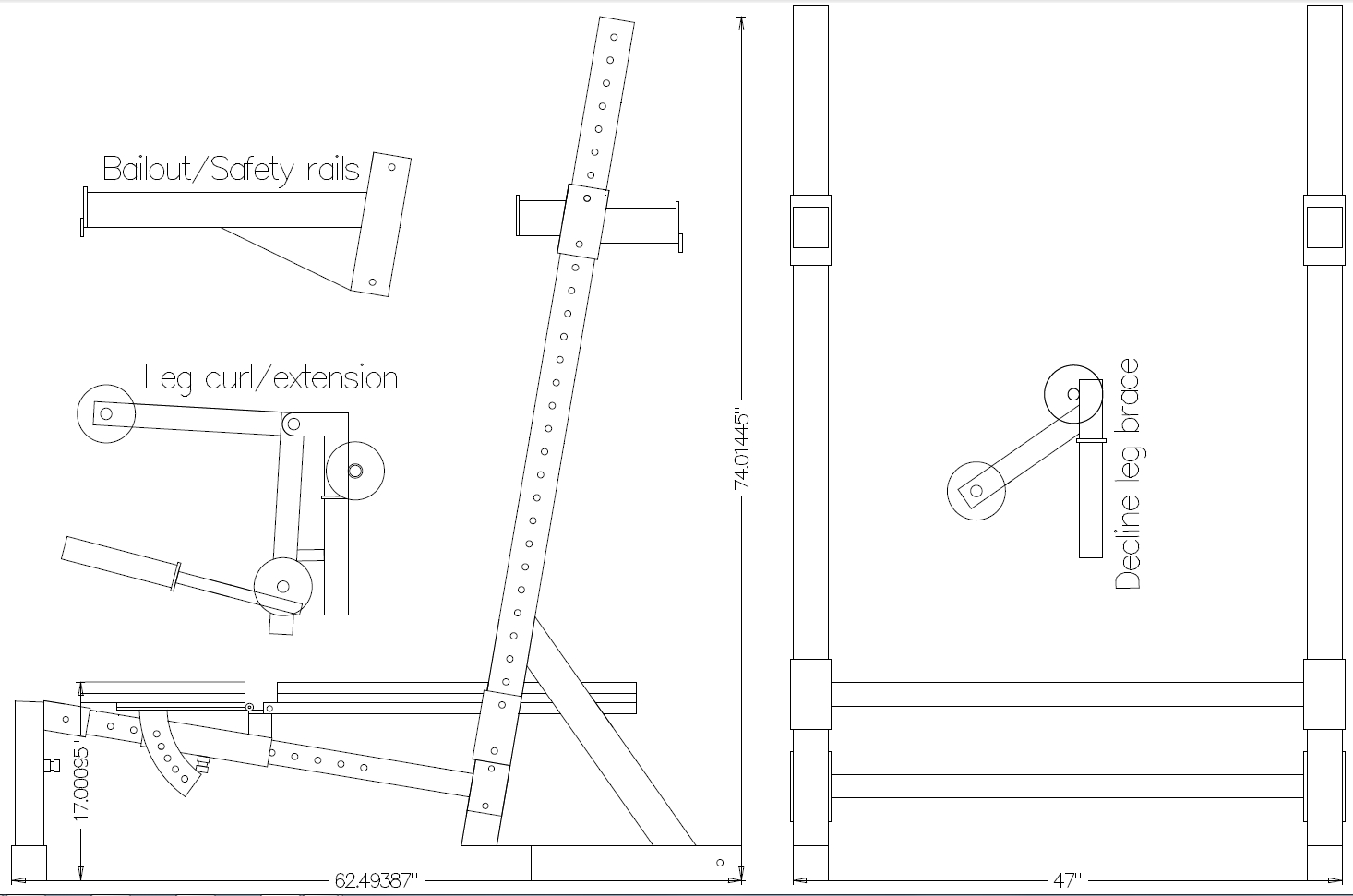

Anyway, here’s the plans I developed based on my requirements. I used a freeware CAD program to develop and test the design, and from there it was relatively easy to get a list of materials, sizes, etc., and once I had everything on hand it was simply a matter of referring to the plan for lengths, cut angles, weld locations, etc.

Plans include bench, safety rails for both squat rack and bench press, leg curl and extension attachment, and leg brace for use with decline bench press

Lets get to the actual build. Click HERE!

.