Hard to decide whether a kukri is a knife or a sword. In spite of the fact that the blade on this design is 15″, technically I do believe a Kukri is considered a knife so thats where I’m going to file it..

This design is inspired by Jason Knight style kukri’s with a bad-ass looking top ridge/harpoon point and a wide fuller, and will feature a full tang. Since Jason Knight inspired it, I might as well use his favorite (currently) steel, 80CRV2

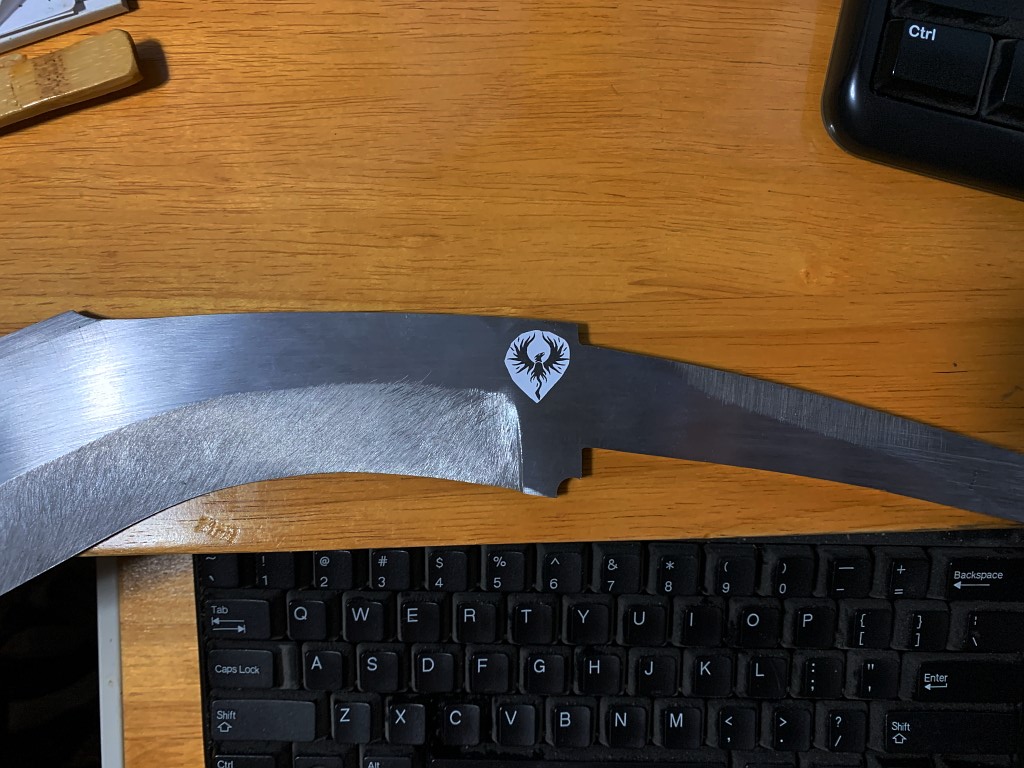

OK, first things first. I made a template out of plywood. This is useful both when forging the basic shape, and also when grinding the profile

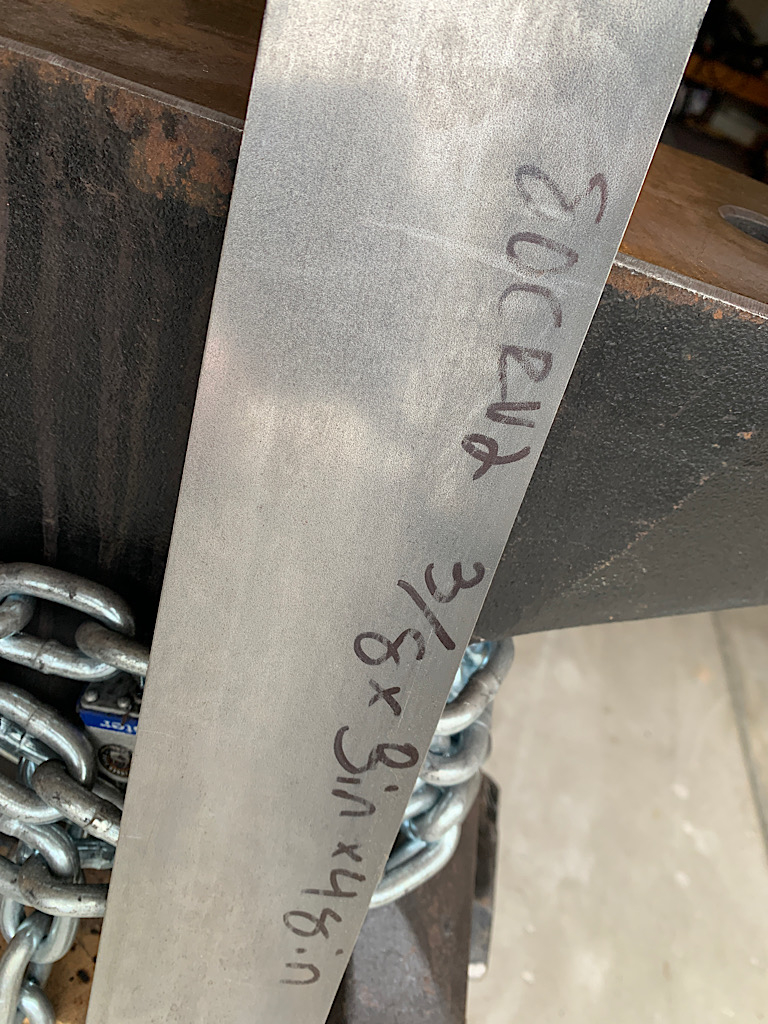

Raw materials. This is a 3″ x 3/8″ x 48″ bar of 80CRV2

the bar is wide enough that I could have just cut/ground the taper down to the tang, but thats pretty wasteful. Forging is better. I drew it out, created the rough profile taper, and hammered it into roughly the curve of the final blade.

Then cut the piece off at an angle roughly matching the tip shape,

More forging brings it closer to final dimensions, more specifically in thickness. The initial stock is 3/8″ which, when combined with the large dimension of the blade, would make for a pretty heavy knife, so I’ve also forged the thickness down to 1/4″ throughout the entire length.

Once roughly ground to profile I normalize the steel via multiple heats of decreaing temperatures and allowing it to cool to room temp in between,

Roughing out where I plan to grind the bevels

Here I’ve ground off the forge scale and decarb left over from forging and normalizing

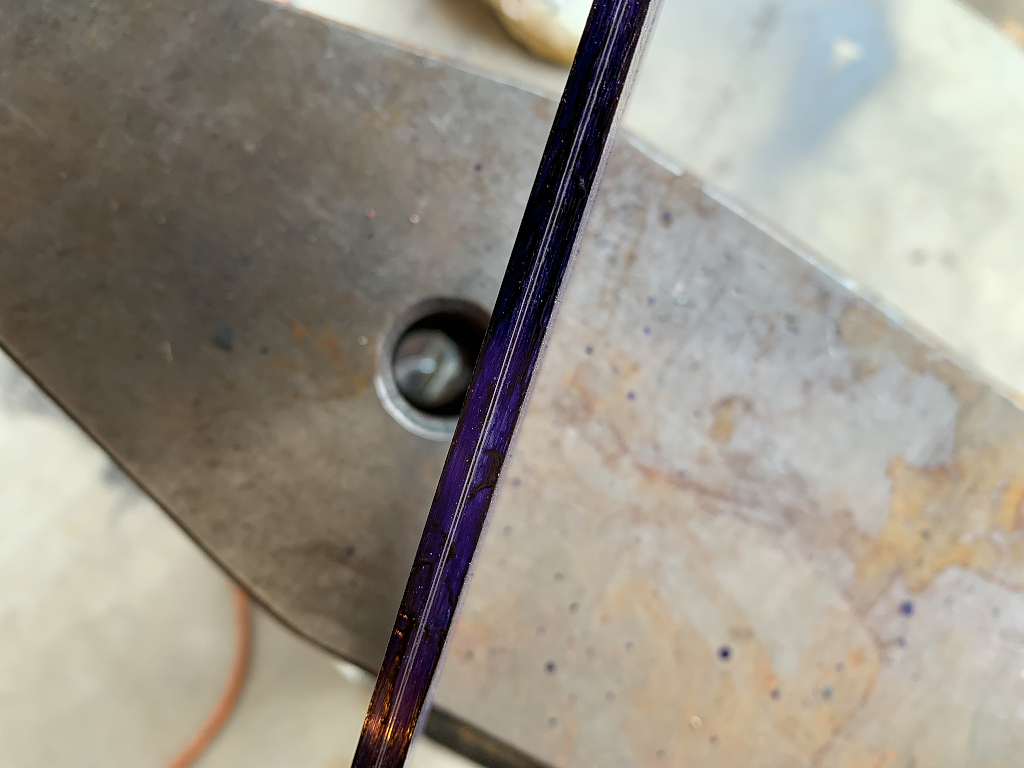

Next, using hand files, I grind the false edge along the top spine of the blade.

The false edge is not sharpened, so its mostly for aesthetic purposes. I think they look cool 🙂

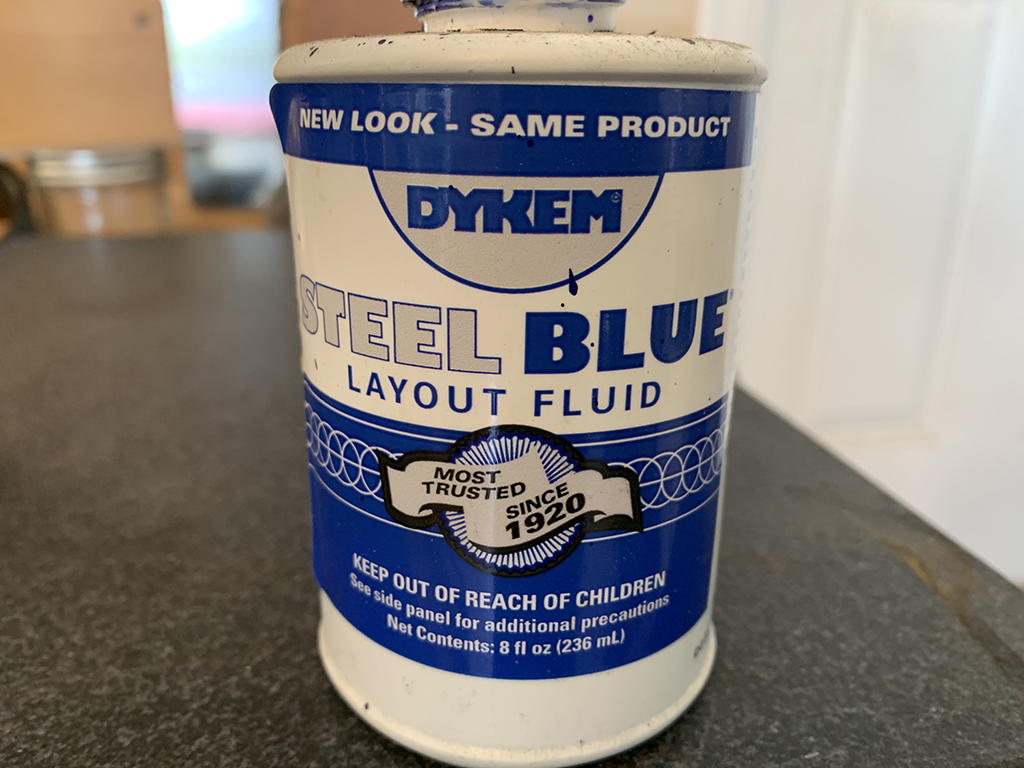

Grinding the bevels in this case starts by coating the blade with layout fluid and then scoring lines that mark the center of the edge, and where the plunge lines and grind will end on the sides.

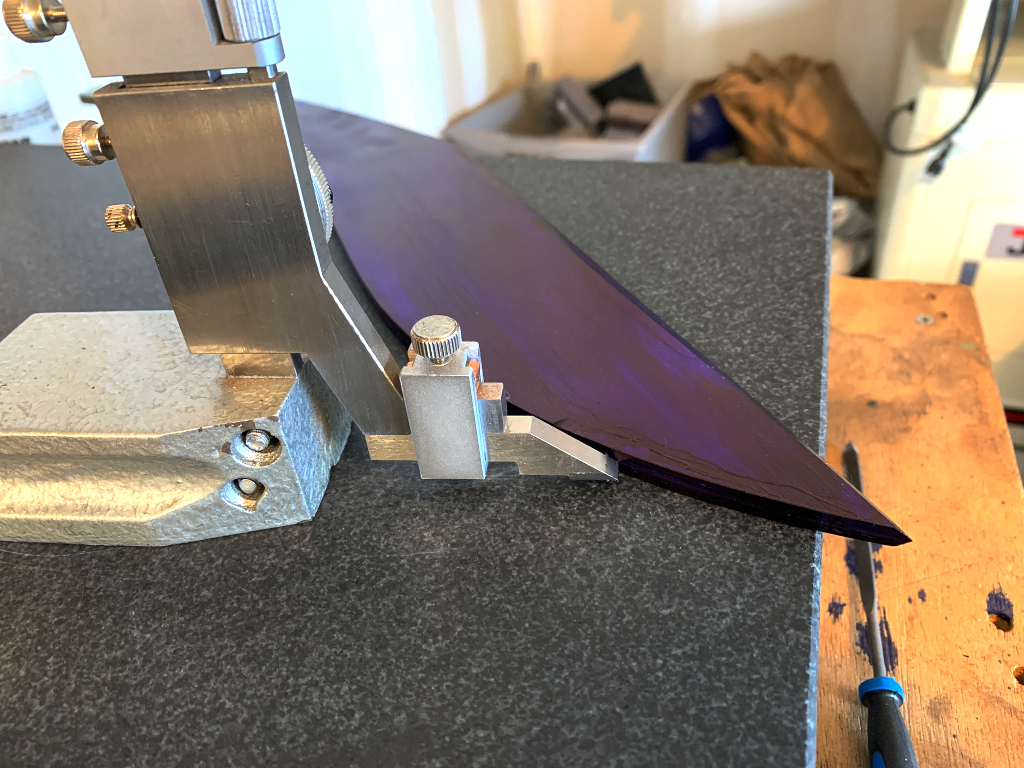

Then its on to the grinder for a few hours of work. the file guide clamped to the blade keeps the plunge lines even from one side to the other.

After the bevels are gound, then the sides get cleaned up on the grinder as well.

To remove any ripples or unevenness on the bevels I then file them flat by hand using a mill file